bull nose end mill definition

The ball nose end mill has the best effect on the machining curved surface but the chip discharge performance is poor because of the small chip holding groove at the tip. 2014-01-14 Ball nose end mills by definition have zero diameter at the tip and therefore in theory must be run at infinite speed to cut at all.

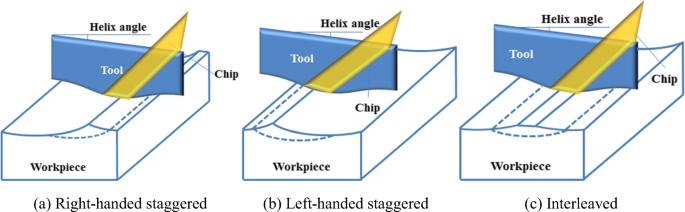

Research On The Tool Wear Mechanism Of The Wave Edge End Mill Based On The Tool Chip Contact Analysis Springerlink

Is the leading manufacturer supplier and exporter of Bull Nose End Mill in Taiwan.

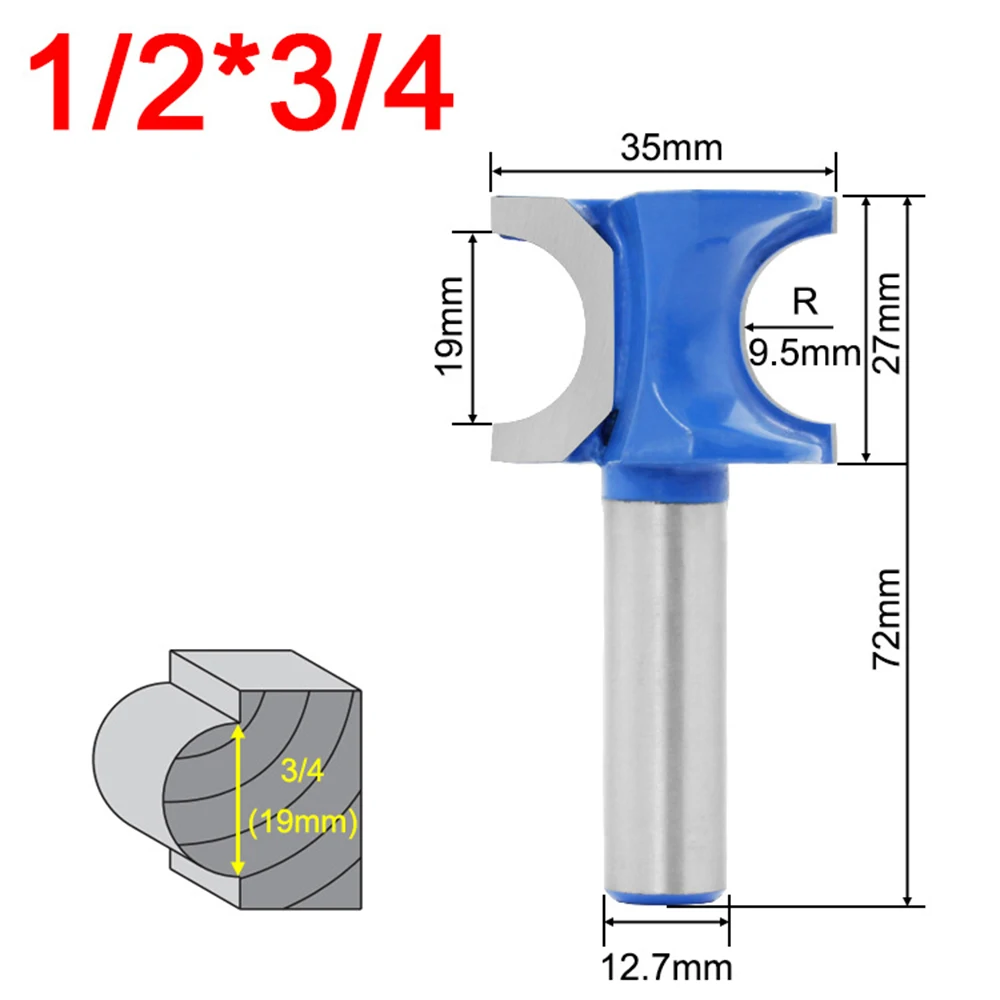

. An end mill is a type of milling cutter a cutting tool used in industrial milling applications. For example it may be a 20 mm diameter cutter with a 2 mm radius corner. Display Obsolete Products Key Filters.

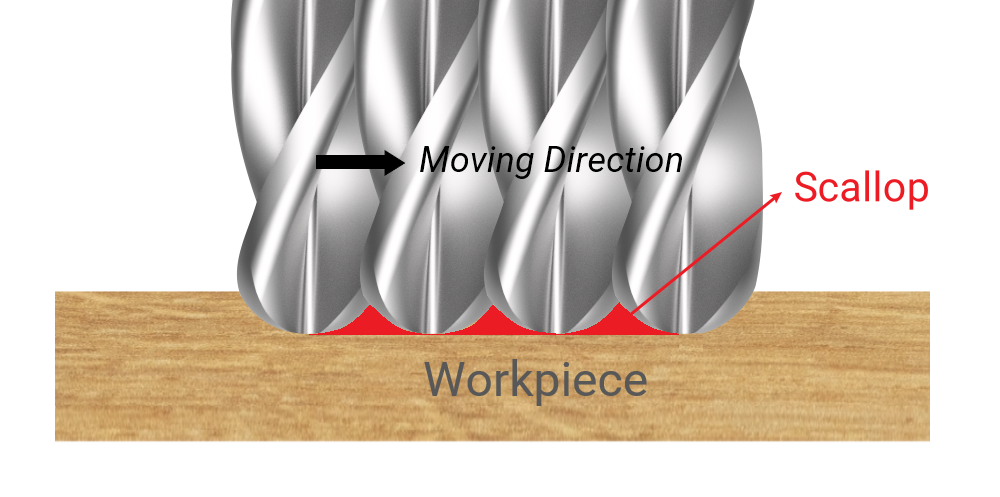

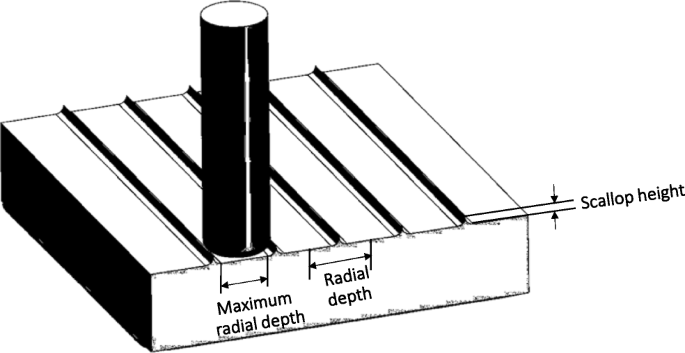

Bull Nose End Mills Corner Radius Bull end mills are simply corner radius end mill cutters. Our range is available in varied sizes and. Profile milling covers multi-axis milling of convex and concave shapes in two and three dimensions.

Ball nose end mills are ideal for machining 3-dimensional contour shapes typically found in the mold and die industry the manufacturing of turbine blades and fulfilling general part radius requirementsTo properly employ a ball nose end mill with no tilt angle and gain the optimal tool life and part finish follow the 2-step process. Hwe Der Machinery And Hardware Pty Ltd. Our expertise allows us to offer a comprehensive range of products in order to meet the international quality standard and they are perfect to use in various places.

A ball end mill is not the same as a corner radiusbull nose end mill. They are used for a host of milling operations from contouring and profiling to slotting and corner picking. Not all mills can cut axially.

Low-Carbon Steels Long Chipping C. These radius end mills are single ended tools used for making corner. 625 shows WEBNHE performing up milling operation.

The cutter diameter is often the first thing machinists look for when choosing a tool for their job. End mills are used in milling. Can you get away with it.

To find and shop the best Bull Nose Mill you need to know about the highest quality of Bull Nose Mill manufacturer supplier wholesaler distributor OEM and ODM from a factory in Taiwan. The silhouette is essentially a rectangle with its corners truncated by either a chamfer or radius. Bull Nose End Mills KDMT Bull Nose End Mills KDMT.

Display Obsolete Products Key Filters. Corner Radius end. All are center cutting allowing plunge cuts into a surface.

Mechanics of wavy-edge bull-nose helical end mill. We have a precise End Mills Definition. Fast-Cutting Carbide Ball End Mills.

Ball Nose Milling Without a Tilt Angle. Copy Mills Bull Nose End Mills KDMT Bull Nose End Mills KDMT. These radius end mills are single ended tools used for making corner radii at the bottom of a milled shoulder.

When the end milling cutter rotates the midpoint of its bottom edge is relatively static and does not have any cutting and chip removal so it can not cut vertically. Ball-end or bull-nose end mills are mainly used for copying operations of complex surfaces the application being known as sculptured surface milling SSM. Read customer reviews find best sellers.

Corner radius end mill cutters have a stronger milling edge than square end mills so feed rates may be increased and yield longer tool life and greater productivity. Made of cobalt steel these end mills have good heat and wear resistance so they can run at high speeds in hard material. Variable spacing between the flutes reduces vibration allowing these end mills to provide fast cuts smooth finishes and long tool life.

A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds. It is distinguished from the drill bit in its application geometry and manufacture. Ball nose end mills also known as full radius end mills or ball mills are cutting tools where the nose radius is equal to half of the diameter of the tool.

This type of tooling features flutes with no flat bottom rounded off at the end creating a ball nose at the tip of the tool. P Steel 79 P0. The ball has a radius with its center point at the center of the end mill.

The square end mills usually use side edge removal margin the cutting depth is generally 1D equivalent to the cutting diameter and the cutting width can also reach 025D. Bull Nose End Mills Corner Radius Bull end mills are simply corner radius end mill cutters. A bull nose cutter mills a slot with a corner radius intermediate between an end mill and ball cutter.

Often used for slotting and pocketing cuts in mold and die making they have a 90 profile and rounded corners which reduce flute breakage and chipping. Browse discover thousands of brands. 1 the definition of geometric parameters creating primary points.

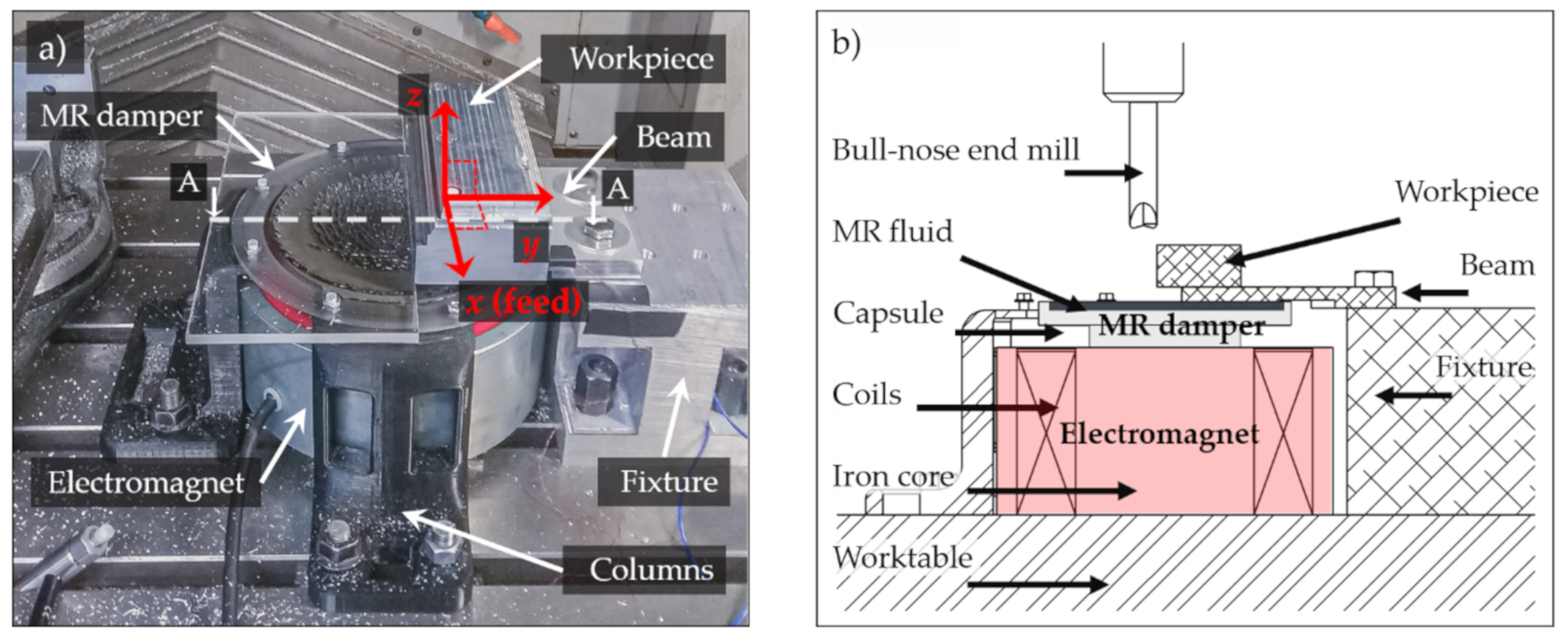

A photograph of the investigated WEBNHE is shown in Fig. Moulds dies and blades milling are usual examples of this category. Echaintool Precision is definitely your good choice.

The machining process should be divided into at least three operation types. P Steel 79 P0. Made of solid carbide they are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material.

Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing. Hwe Der Machinery And Hardware Pty Ltd. Ball nose end mill is a kind of tool which is assembled on the milling machine with the cutter similar to the ball head and is used for milling various curved surfaces and arc grooves.

2 the rotation of primary points to create knots. A tool with larger radii can also be referred to as bull nose Ball Profile End Mills. Those designed to cut axially are known as end mills.

The geometric simulation involves. While a drill bit can only cut in the axial direction most milling bits can cut in the radial direction. The larger the component and the more complicated the configuration to the machine the more important the profile milling process planning becomes.

Bull Nose End Mill Cutter. Known as one of famous Precision End Mills Manufacturers and Suppliers in Taiwan we have a wide range of products for sale. Low-Carbon Steels Long Chipping C.

This creates a constant single radius or ball at the tool end with no straight edge sharp corners in the profile. Looking for 45 degrees bull nose end mill please refer to our 2 flutes and 4 flutes bull nose end mill.

Ball End Mill An Overview Sciencedirect Topics

Applied Sciences Free Full Text Semi Active Magnetorheological Damper Device For Chatter Mitigation During Milling Of Thin Floor Components Html

The Buzz At The Hive The Tavern Hive Punch Recipes Punch Recipes History 18 18 Century Art

Long Neck Bull Nose End Mills Osg Pdf Catalogs Technical Documentation Brochure

Cnc Router Bits Basics Terms And Common Types Snapmaker

Common Types Of End Mills 3 1 Voxel Based Mrr Expression Of The Download Scientific Diagram

Nw Half Round Bullnose Router Bit 8mm Shank Woodwork Milling Cutter Type 6 Hand Tools Home Garden

Modeling Of Thrust And Torque For Drilling Ptfe Materials Springerlink

Long Neck Bull Nose End Mills Osg Pdf Catalogs Technical Documentation Brochure

Long Neck Bull Nose End Mills Osg Pdf Catalogs Technical Documentation Brochure

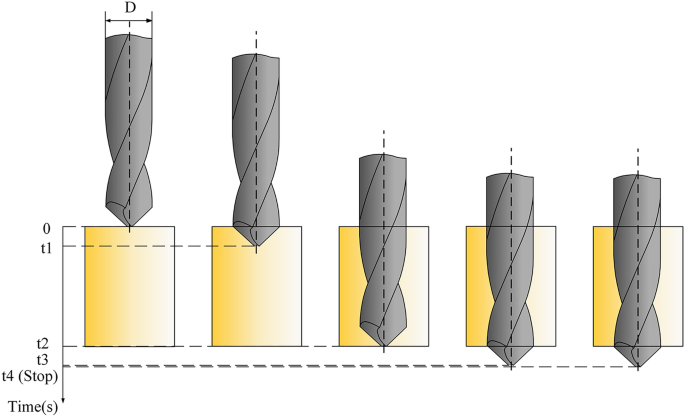

Main Cutting Parameters In Milling Operation With A Bull Nose End Mill Download Scientific Diagram

Steel Pentacle Septum Clicker Septum Piercing Jewelry Septum Jewelry Body Piercing Jewelry

A Novel Convex Hull Method For Optimum Multi Point 5 Axis Tool Positioning For Machining Of Complex Sculptured Surfaces Springerlink

Test Part Machining Left Bull Nose End Mill With Corner Radius And Download Scientific Diagram

Pdf Parametric Modeling Program Of Fillet End Mill Semantic Scholar

Solved Tapered Mill Tool Setup Help Autodesk Community Fusion 360